Gravure's Advantages on Gradient Printing

Sentien's gravure printing has some advantages in gradient printing, which are mainly reflected in its technical characteristics and applications:

Fineness and resolution: Compared with screen printing, gravure printing technology can achieve a higher degree of fineness and resolution. This is crucial for gradient printing, which requires smooth color transitions, while reproduces subtle patterns and details more accurately.

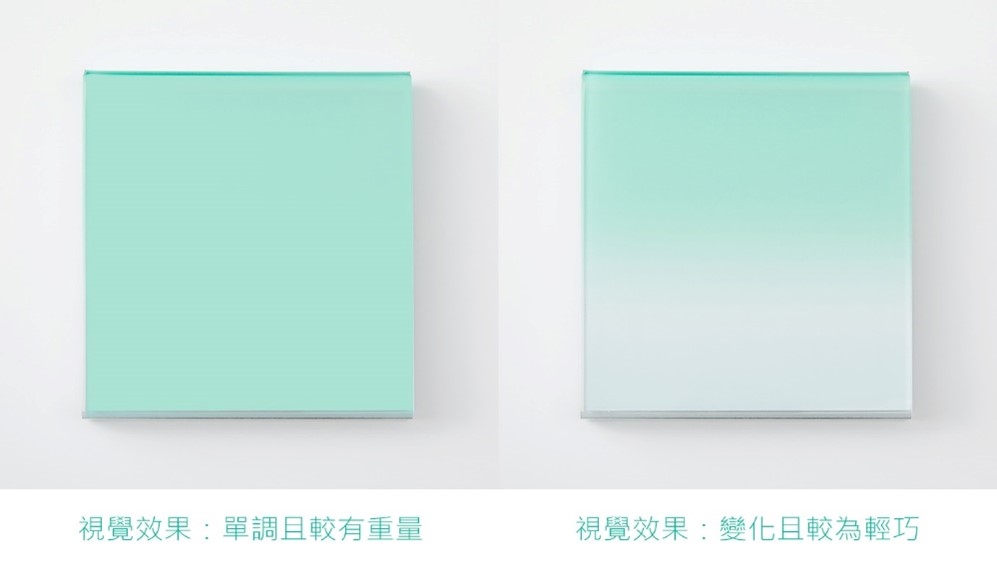

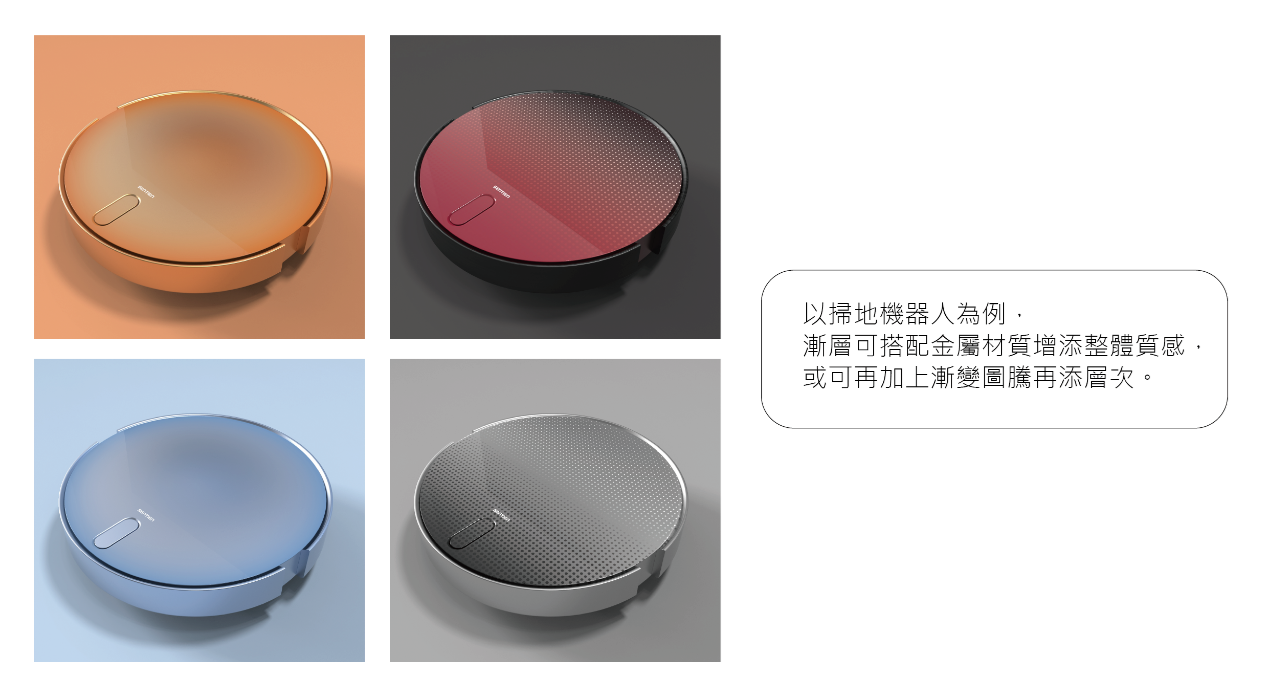

Depth and layering: Gravure printing creates a sense of depth and layering, which is very beneficial for the presentation of gradient effects. Through unique process of gravure, the visual effects of gloss, shadow and depth can be created.

Color Management: Gravure printing technology has excellent color management capabilities. This means that during the gradient printing process, the transition of colors can be more precisely controlled and managed, resulting in more accurate color reproduction.

High production efficiency: Gravure printing has high production efficiency, which is very beneficial in situations where large quantities are required. Fast printing speed and high efficiency ensure that large quantities of prints completed quickly.

Generally speaking, advantages of gravure printing over gradient printing are reflected in its high definition, excellent color management, depth and layering performance. This makes gravure printing an effective printing technology for achieving high-quality gradient effects. If you would like to increase the visual appeal and uniqueness of your product, please consult us.

|

|