The process of molding and ink transfer occur simultaneously. This is a non-spray method which can be applied on curvy product.

Feature of our In Mold Decoration Flim

When discussing the characteristics of In Mold Decoration Flim, it is important to recognize his role in the forming process. The process of foil passing through the foil feeder into mold and decoration while molding. It is a cost benefit and environmentally friendly method for mass production with precision alignment. The UV coating highly enhance the reliability and vale of the product, also provide various texture like glossy, matte, embossed and soft touch to customer.

Our In Mold Decoration Flim is a special silver-ion in mold decoration process that can be applied to any kind of shape of plastic parts, such as sheets, pipes, profiles and other structures. With silver ions deposited on the surface of your plastic components it provides an antibacterial effect (against bacteria including E. coli and S. aureus, etc.) while remaining aesthetically pleasing and being visually appealing.

Application for automotive and other fields

This special form of flim will play a key role in injection moulding operations with some special needs. This novel technology can be applied in many fields, such as consumer electronic products, appliances, automotive Interior components.

The strength of In Mold Decoration

In Mold Decoration is characterized by a hardened transparent film on the surface, a printed pattern layer in the middle, and a plastic layer on the back. Because the ink is sandwiched between it, the product can prevent the surface from being scratched and abrasion-resistant, and can maintain the color's vividness for a long time.

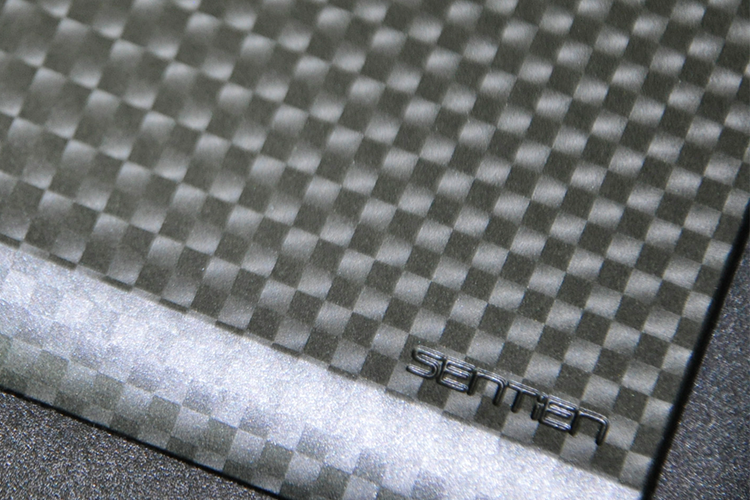

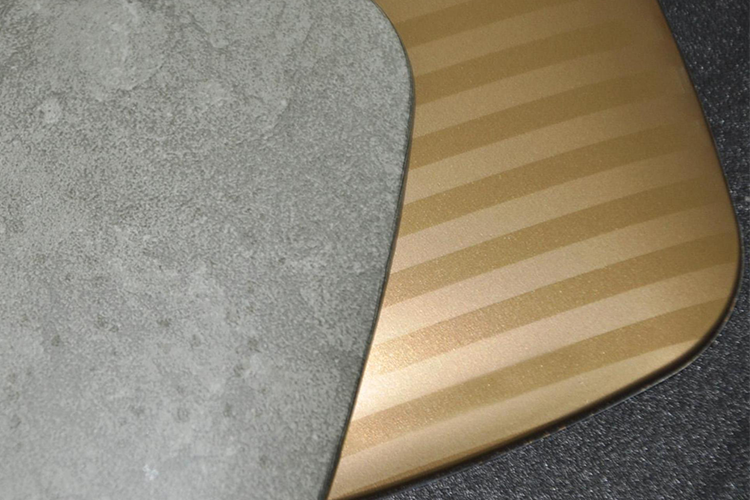

IMR Effects

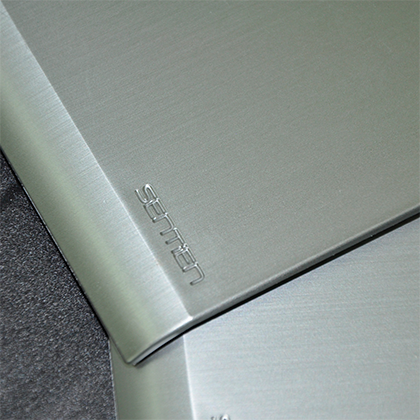

Glossy

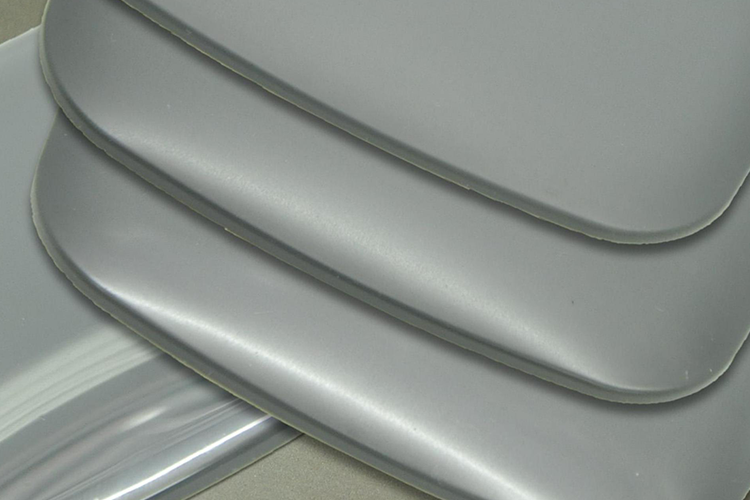

Matte

Hairline

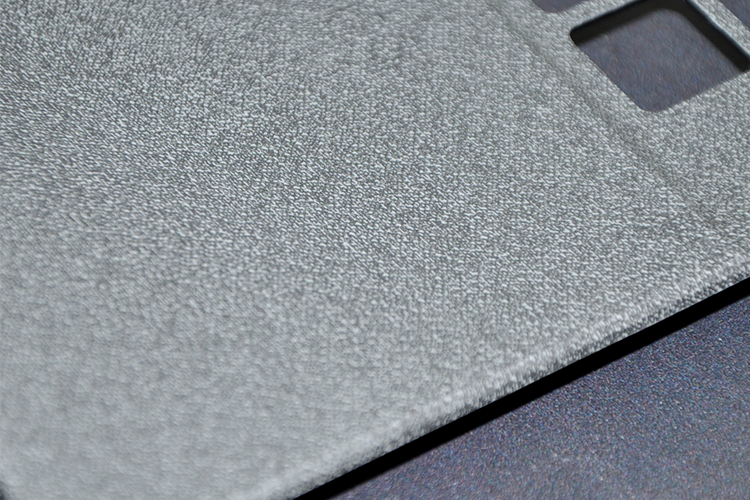

Soft Touch

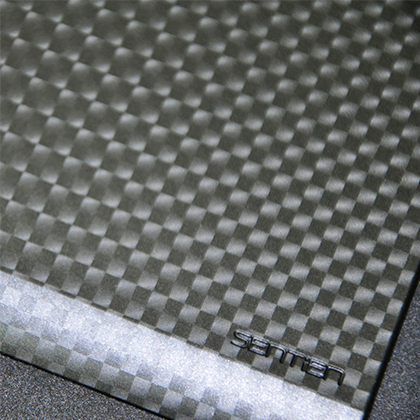

Emboosed

NCVM

Partial Matte

Antibacterial

Program

Non IMR mold can use manual method to apply

IMR film into the mold and see the exterior outcome.

We suggest using special IMR mold with

specific frame and suction equipment to avoid negative effect like wrinkle,

bubble, crack, delamination, etc.

Standard injection machine with film feeder and specific IMR molding.

If the product requires UV layer (H.C. ), UV Machine

is required for curing purposes.

The quoting based on the size and visual

effect of the object.

The most commonly effect are gloss, Matt and hairline.

The recently developed embossing process

can simulate the bionic effects of mold biting, sandblasting, carbon fiber, and

natural texture.

Advantages—Injection and decoration can be

done at the same time.Using IMR technique eliminates the cycle time of

production and enlarge the capacity.

Automatic production flow can be designed

with roll-to-roll IMR film. IMR is an environmental- friendly decoration

method.

Disadvantages— There are restrictions on

the design of the product. Products with small R corner and deep wrapping angle

is not suitable for IMR. The minimum order quantity is comparingly high.