Film Insert Molding Basic Guides

What is Film Insert Molding ?

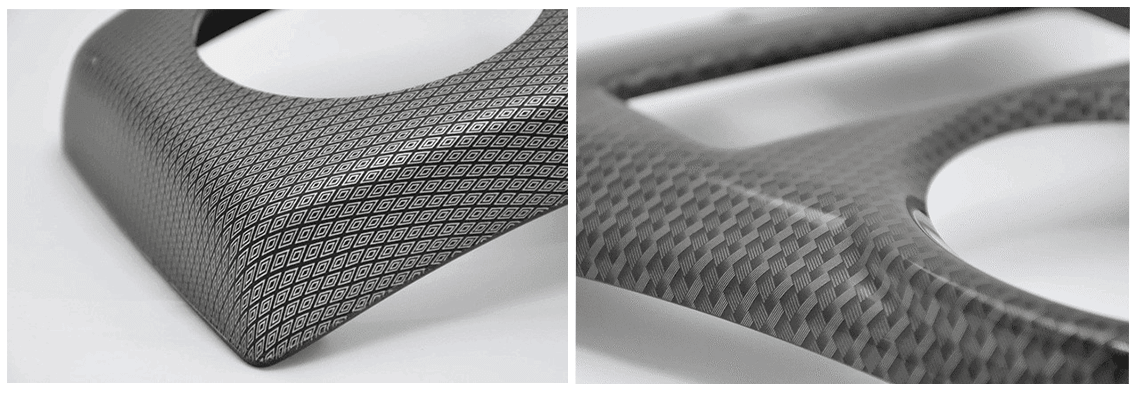

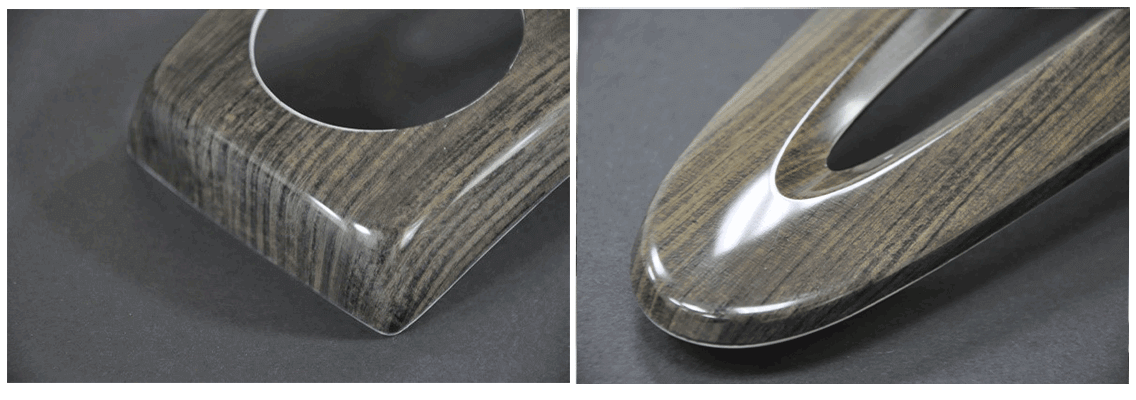

Film Insert Molding(FIM), also known as INS, is part of In-Mold Decoration. A technology that allows you to put virtually anything you want on a plastic component. The pre-printed film(or foil) is inserted into the mold cavity and thermoformed, which combines the advantages of decorative and functional graphics with a plastic molded component. This decorative film laminate is widely used. Automotive interior is one of the most common in-mold decoration examples.

In Mold Decoration Automotive

In the luxury vehicle market, the interior is usually one of the highest priorities for customers. Car manufacturers used wood or leather for a range of components, from decorative panels on the dashboards, audio, navigation systems to air conditioner. Then, metal and other lighter, more resistant materials gradually replace wood and leather. Automotive manufacturers are now using Film Insert Injection Molding to replace metal and other heavier materials for car interiors.

Advantages of Film Insert Molding

Here are a few advantages that Film Insert Molding is beneficial for automotive plastic parts production.

-

Lower VOCs(volatile organic compound)

-

Higher levels of decoration and cost saving

Auto trends clearly create demands for lower VOCs in automotive interiors, there’s a growing challenge for OEM material and design engineers as well as suppliers. Film Insert Molding Technology is the new way to replace typical processes such as coating or painting, significantly lowering down the number of VOCs emissions.

Consumers demand higher levels of decoration in vehicle interiors, automotive OEMs are forced to find a way to satisfy market demand without increasing costs. In-Mold Decoration can expand the boundaries of design and functionality to injection molded automotive parts with considerable savings in costs, time and capital investment of facilities.

Film Insert Molding Process - 5 Key Stages

Film Insert Molding is a one-step process. This offers manufacturers extensive flexibility in design and manufacturing. The process includes 5 key stages :

-

Printing

-

Forming

-

UV Curing

-

Cutting or trimming

-

Injection Moulding

How to Select Film Insert Molding ?

Selecting the right Film Insert Molding Manufacturer is one of the most important criteria in making quality auto parts consistently and profitably. A qualified manufacturer will help keep costs lower and make you more competitive.

-

Experience on diverse projects

-

Vertical integration

-

Green sustainable solution

A manufacturer with various aspects of in-mold decoration projects can design films from the ground up, and not only understand the real-world solutions to the problems that OEMs want to solve, but also identify when designs or solutions suggested by demander might not be the best, but propose further designs or solutions.

Having a partner with one-stop IMD/FIM integration, who can provide primary solutions for printing, forming and molding services. They include equipment and tooling. You can also get additional solutions and resources such as design and processing input for part design, printing and molding.

As global warming is a problem that isn’t going away. Countries around the world have committed to reaching carbon net-zero by 2025. Addressing sustainability across all industries is a worldwide priority. Especially in the auto industry, to develop sustainable solutions including processes or equipment becomes necessary.

With over 70 years, Sentien occupies the 1st market share in In-Mold Release(IMR) for consumer electronics projects in the world. We can provide design and engineering input for the entire INS(or FIM) supply chain.

Sentien has also stepped up to the challenge of sustainability business and focused on reducing waste and minimizing its footprint. An investment of RTO (Regenerative Thermal Oxidizer ) was developed to destroy VOCs in process exhaust air before it pollutes the environment.

With Sentien In-Mold Film Insert Molding, you can apply partial, full-surface, or even two-sided decorations on flat or curved surfaces. From shiny to matt, carbon to chrome, any designs you want to have a look from auto interior parts. Please contact us today.